Description:

In general, CNC corner forming machine is one type of cold roll sheet metal forming machine. The machine will use forming roller and square tool to form corner perfectly. Because The panel corner is completely formed, no more any welding and polishing like before. At same time, the panel top surface will be protected very well. Obviously, It is high efficient equipment for equipment control products such as panel, electric cabinet door, aluminum roof or buckle plate corner forming and so on.

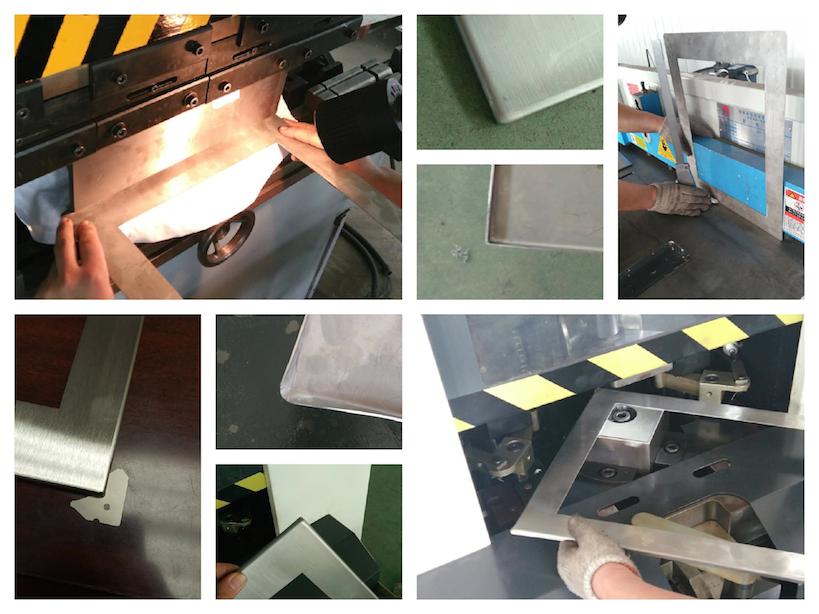

Machine Parameters:

Machine Parameters:

Machine Characters:

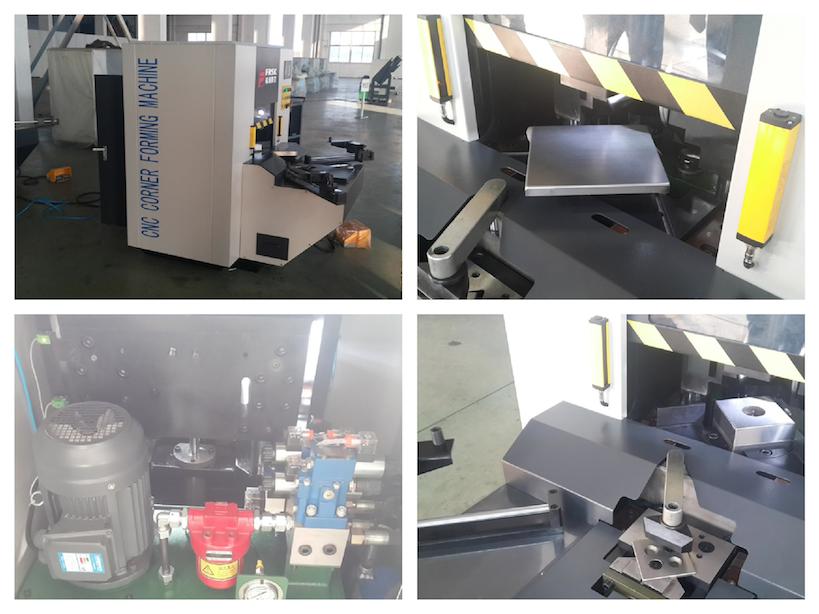

1. First, CNC controller is touch screen + PLC to control tool gap and working process.

2. Servo motor + ball screw control roller to square tool gap according to plate thickness.

3. Then hydraulic station drives roller to finish forming.

4. Square inner support has 4 corner. each corner can be identify different inner radius according to thickness;

5. For sure, we care more about people protection. Optic safety curtain will protect operator in operating area.

6. Pneumatic safety door is with protection plate for work piece panel top surface. so that the door will automatically open/close according to working process.

7. On another hand, Compact hydraulic valve block give machine with enough working force and easy maintenance.

8. As second step, hydraulic corner shear will cut the scrap edge after corner forming;

9. In general, two step foot control switch can control corner forming and scrap corner cutting;

10. Two adjustable support arms will help operator to handle bigger sheet panel easily and finish corner forming perfectly.

11. Especially, There is special guiding structure for high edge corner forming;

Benefits of CNC Corner Forming Machine:

- NO MORE WELDING, GRINDING/POLISHING, KIDDING!

- BATCH PRODUCTION FOR METAL PANEL CORNER FORMING!

- EASY OPERATION AND HUMAN PROTECTION!

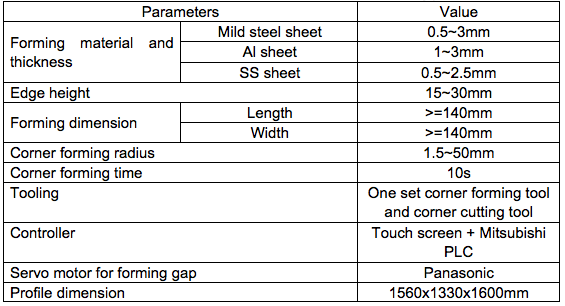

Corner Forming Process:

1. At beginning, we cut flat plate by shear or laser into required shape.

2. Then, use Hydraulic Press Brake to bend panel side edge (leave corner unbend).

3. Third, Put target panel corner over square tool and stamp on foot switch to do roll forming.

4. At last, Put formed corner on shear station to cut the scrap edge. finally, one corner will be finished.

Suitable Metal Material:

Generally speaking, It will be suitable for most panel plate, like MS/SS/AL/COPPER, With or without coating. While because of metal forming principle, we shall take care of corner plate thickness, edge height and angle.