Description:

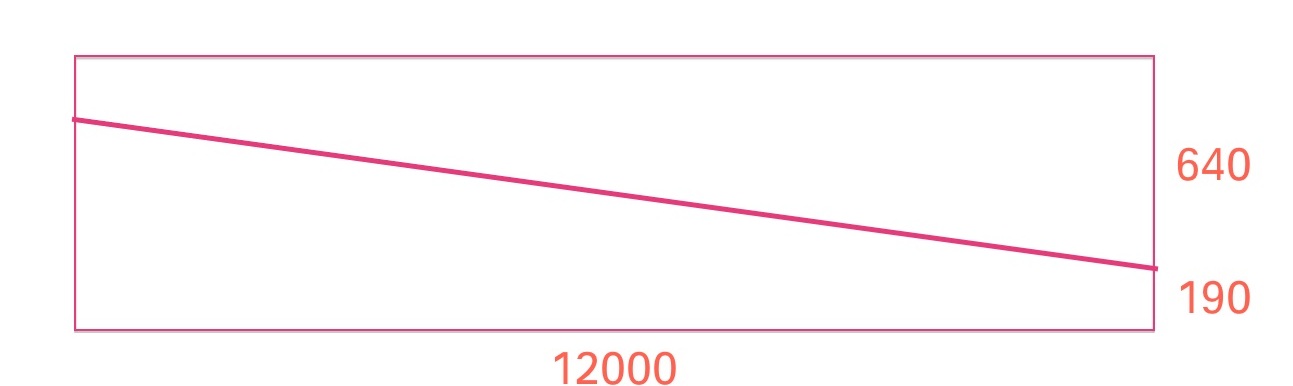

Normally we apply Light poles along public road/street. The height can be 8, 10, 12, 14m. The pole dimension can be about 60mm at small end and about 200mm~340mm at the big end. It is clear that with the road construction more and more world widely, This type pole quantity is the biggest required and high competition. So increase production speed and reduce production cost is very important. For sure, Most effective production equipments and process shall be used. Generally, The pole can be polygon or conic type, one seam welding. Plate thickness is 3~6mm.

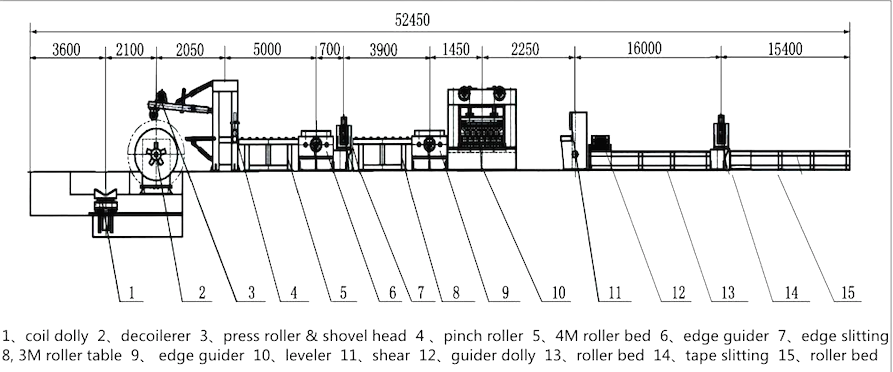

The light pole cut to length machine not only can cut coil sheet into rectangle piece, but also can cut taper shape plate. Normally the raw material is hot roll steel coil. the pole is with small end and big end according to pole shape. so we shall make the plate uncoil, flat and into Trapezoidal plate.

Technical Parameter

- Thickness of material:2mm-6.0mm for Q235A hot rolled mild steel

- Width of material:800-1600mm

- Weight of steel coil:Max 15 tons

- Inner diameter of steel coil:Φ500mm-Φ750mm

- Leveling speed:5- 15m/min

- Number of leveling rollers: 13

- Leveling rollers diameter : 130mm

- Length range for scale: 2000~14000mm according requirments.

- Tolerance of cutting length :±15mm (base on 8m length plate)

- Main leveling motor power: 37kw (total about 65KW)

- width area for machine:about 7000mm

Advantages of Our Light Pole Cut to length Line:

- Mechanic disc blade cutting;

- Fast speed;

- Good straightness;

- No heat stress on the cutting edge;

- Nice cutting edge, no cut ballast;

- Both can be used to cut scrap edge;