Main Features:

- As standard, hydraulic Ironworker has two hydraulic cylinders to work separately for different stations. Dual pump(option) can make two hydraulic cylinder work at same time.

- Basically, Each station has guider or gauge for working accurately;

- Furthermore for plate and profile cutting station, Electric back gauge can trigger section cut automatically ;

- Accordingly, two foot switches are for two hydraulic cylinder control;

- In general, movable lamp can make work more easier and accurate;

- For sure, Punching stroke is easy to be adjusted;

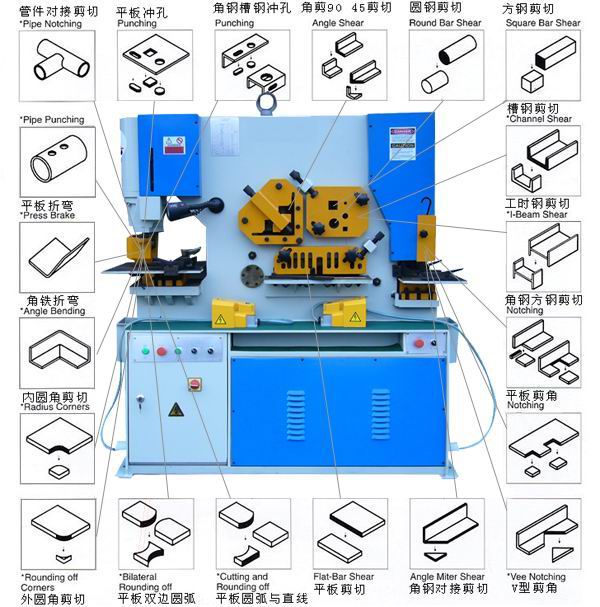

Functions for Each station:

Punching station:

- It is suitable for various hole punching (round, square, oval and other special design).

- with press brake tooling, we also can do plate/angle steel bending. Or we can do notching with tool (corner cutting for plate, angle steel).

- Tube notching.

- Louver Punching.

Plate Shear station:

Sheet metal cutting is just like narrow hydraulic shearing machine and Angle steel corner cutting.

Profile section Cutting Station:

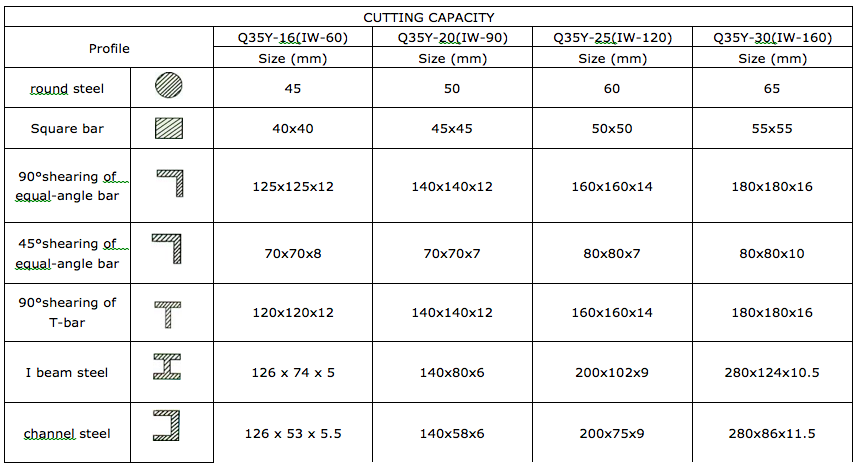

- Round/square bar cutting; Angle steel cutting;

- H-beam cutting; C-channel cutting; (Optional, need drawing to check)

Standard configuration:

- 3 different size round punching tool(up/down)

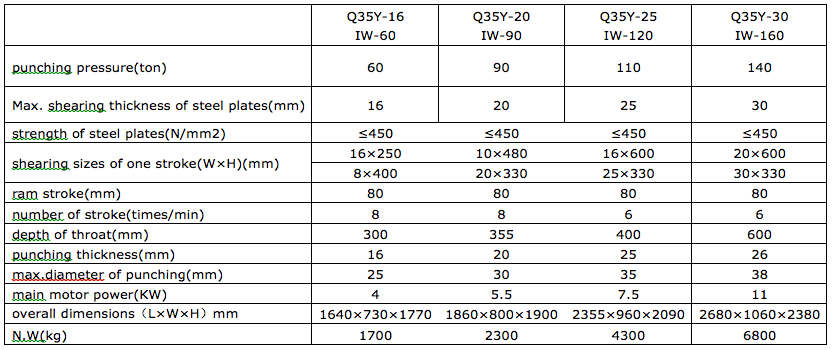

- Angle steel cutter (according follow data) Round bar/square bar cutter (according follow data)

- Notching cutter Guider/measuring gauges for punching, shearing station

- Automatic back gauge for section cutting (angle steel/round and square bar)

- Movable working lamp

Options:

- Special section cutter (H-beam, T-section, C-channel need profile dimension/material info to design)

- Tube notching (need tube size, dimension to design)

- Plate Bending (Optional hydraulic press brake Punch / multi-V die) Shutters forming tool (need drawing to design)

HYDRAULIC IRONWORKER WORKING VIDEOS:

If need, Punching station can be used for shutter press forming.

If we want to bend angle steel, first we can do notching to cut V. then we use press brake tool to finish bending.

Hydraulic ironworker can do corner or middle notching for C-channel. Surely, we have to work with related tooling.

It is clear that we can do round, square, oval hole punching with proper punching tool. we also can use combined tooling to punch various thickness washers.

According to customer requirements, profile cutting station can be exchanged with various blades for C-channel, H beam, T profile and other profile cutting.

We can design different Hydraulic ironworker tooling according to customer’s machine capacity or workpiece. For example, Multi-hole punching can improve working speed for customer.

As another application, We can use punching station to do tube notching.

normaly angel steel 90/45 degree cutting is very common requirements. If want to cut bigger or special dimension, please contact us.

In general, angle steel corner cutting can be used for 90 degree angel steel welding.

We can not only do hole punching on plate, but also can punch various on angel steel.

Flat plate corner cutting is very common for steel cabinet fabrication. So that this station is also very useful.

with flat plat Hydraulic shearing station, we can cut most narrow workpiece easily .