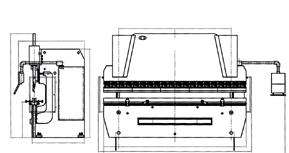

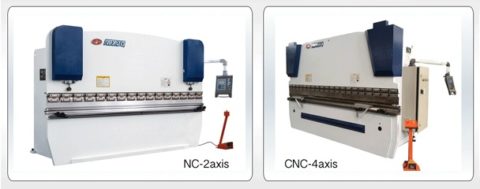

Electric-hydraulic synchronised type (Y1-Y2) Press Brake, optional back-gauge up to 6 axes control, European CNC controller, Hydraulic, electric control system...

47 Years History In design and Produce hydraulic Press Brake and Hydraulic Shearing machine

Multi-machine CNC Electric - hydraulic synchronised press brake, Max length can be 12- 24m, Can be with 2~4 units, Full bending procedure is with CNC control...

Hydraulic guillotine and swing beam shear, Cutting thickness can be from 4mm ~ 30mm, Shearing length up to 8m per single machine Can be with CNC controller...

Features Of JINIU PRESS BRAKE

CNC Hydraulic Press Brake and Plate Hydraulic shearing machine are common machine for sheet metal fabrication. With long term developing, JINQIU already marked self characters on machine design and production. We have complete products line, Developed machine design, improved machine processing, thoughtful customer service.

-

47 Years History of Hydraulic Press Brake / Sheet Shearing Machine Design Production

JINQIU was established in 1969 as national enterprise, changed into private company in 1990’s. From 1979, we started to produce hydraulic press brake and shearing machine. We were one of earliest manufacture in china, key sheet metal sheet equipments supplier. JINQIU brand is famous brand in china.

-

24 Hours Service Call, Over Sea Big Bending Machine Installation and Training

We started machine exporting from 1990’s. “SERVICE is also part of our product.” We knew and take it as our duty before sales. So our service phone is 24hrs on line. We will reply customers complain and requirements in 24hrs. All machine trouble shooting shall be given in 2 days. Within warranty, parts shall be delivered by courier in 3 days. Technical guide file shall be emailed at same time.

-

Full Technology and Complete Products Lines of Press Brake / Hydraulic Shear

Now we have finished machines design more than 170, various capacity and style. CNC/NC/ Conventional Hydraulic Press Brakes capacity can be from 30T-3000T, length can be 1.3m – 18m (tandem). Hydraulic shearing machine can be 4mm~32mm thickness, length can be max up to 8m per single machine. With long term developing, JINQIU already developed and absorbed latest technology of sheet metal bending machine and hydraulic guillotines.

-

ISO9001 Quality System, CE, SGS Audited, China High-Tech Enterprise

Company’s all production related processing are under ISO9001 system control. All products and parts are with full record and can be traced. We passed European CE certificate for CNC Hydraulic Press Brake and Hydraulic shear. All our company info is audited by SGS as made-in-china Golden supplier. 1997, QC12K NC front feeding shear got “National New Product”, 1998/2003/2005/2007, “Jiangsu High-Tech Enterprise”

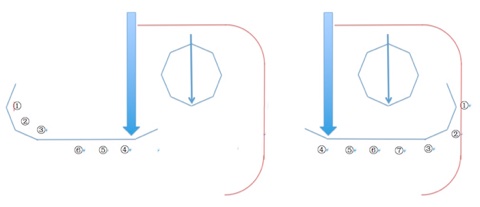

PRESS BRAKE INFO