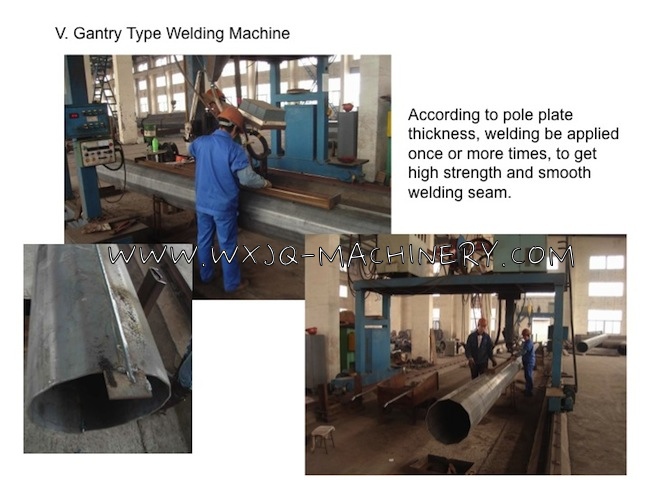

High Mast Pole Automatic Gantry welding Machine

Model: SHL-4000

Application: In general, It is for finally longitudinal seam welding process for high mast .

TECHNICAL PARAMETER

| Rail distance | 3000mm(or 4000mm) |

| Rail length | 15000mm or according requirments |

| High mast Pole diameter | 300-2000mm |

| High mast pole length | 12000mm |

| Welding wire diameter | 3.2-5mm |

| Welding speed | 250-1200mm/min(bi-side driving, variable-frequency stepless speed control)

The AC driver : Telemecanique |

| power | Main motor power:10KW

(not include weder) |

| Profile dimension | 2830×4450×3695mm |

COMPONENT CONFIGURATION

- travel driving motor :YDS100-4 low speed motor 1 set

- welding lifting choose SCWS-08-1.1W deceleration machine 1 set

- flux recovery fitting 1 set, powder bucket 1 set, suction 1 piece, sucker 1×5m

- submerged arc welding machine 1 set

- power cord 3×16m㎡,60m

- arc guidance 1 sets(including welding gun)

- cable movement pulley

- electrical apparatus box 1 set control box 1 set

TECHNICAL DOCUMENTS

- Whole machine foundation drawing

- machine instructions (electrical appliance diagrams, line hanger drawing, V frame drawing)

- packing list

PARTS SUPPLIED BY BUYER

a、24Kg track40m

- Make base according to supplied information

- Gliding wire frame

- welding V frame or roller frame

- lubrication for deceleration machine (machine oil 20#)